Multi-Scale Modelling

Bringing together a world-leading, multidisciplinary team to develop fast, highly accurate models, advancing the development of digital twins to speed up battery development and ensure safe operation for longer battery life.

Accurate simulations of batteries will enable battery makers to improve designs and performance without creating expensive prototypes to test every new material, or new type or configuration of cells. The project considers a range of length scales, from the nanoscale – where atoms interact – up to the macroscale of a complete pack and its electronic control systems. A range of timescales are also considered from the movements of atoms at the nanosecond, through to long-term degradation occurring over years. Battery simulations and design tools exist at each length and timescale, but they have previously lacked the accuracy required for understanding the phenomena occurring within batteries.

The project’s world-leading research bridges science and engineering, working innovatively alongside UK industry to deliver impact. Its internationally recognised experts are developing new digital and experimental techniques for understanding battery behaviour at the atomistic, continuum and system scales. Fast, accurate models, incorporating the most complete physics and advanced mathematical techniques, are being developed to be directly usable for industry, enabling digital twinning of whole cells and packs. Atomistic accuracy will parameterise higher level models and tackle key challenges, such as the complex interactions and activity at the electrolyte-electrode interface. Rapid experimental parameterisation methods are being developed, greatly reducing the time and cost of customising models for specific applications.

Case Study: The Multi-Scale Modelling Project is helping create global collaborative communities:

- PyBaMM (Python Battery Mathematical Modelling)

https://www.pybamm.org/

PyBaMM solves physics-based electrochemical DAE models by using state-of-the-art automatic differentiation and numerical solvers. The PyBaMM Community: - -41 contributors to the project

- -300 Slack workspace members

- -Webinar with 379 participants, a third from industry

- -Faraday Institution Collaboration Award Winners 2021

- DandeLiion

https://www.dandeliion.com

DandeLiion is an ultra-fast solver for electrochemical models of planar lithium-ion cells and thermal-electrochemical models of three-dimensional composite pouch cells. - ONETEP

https://www.onetep.org/

ONETEP is a leading UK-developed code for first principles quantum atomistic simulations. ONETEP is available to UK academics for free.

Timeline with milestone/deliverables (March 2025)

- Expand on the physics and degradation models in PyBaMM (Python Battery Mathematical Modelling).

- Establish a similar common code base for equivalent circuit models (ECMs), called PRISM.

- Examine the processes that occur during the formation cycles of a newly manufactured battery and how this can set the trajectory for its performance and lifetime.

- Develop physics-based models for lithium iron phosphate (LFP) battery chemistries.

- Develop a data set on long-term cell ageing, using rigorously controlled experiments.

- Implement models for advanced state estimation and control.

- Develop digital twins as design tools for new cell and pack configurations.

Project Innovations

A common coding framework – PyBaMM – has been established and multiple degradation mechanisms added. It is an open-source model, which is easy to use and provides a high-quality resource for the battery community to explore the mathematical theories with a minimum of coding effort. The PyBaMM community continues to grow, with users and developers from industry and academia around the world.

Rigorous, standardised parameterisation techniques have been developed and the spin-out About:Energy was formed to provide parameterised models as a service to increase access for industry.

Improvements to atomistic modelling were released as part of ONETEP and an ultrafast solver called DandeLiion has also been developed, which is optimised for speed. The physical models in both PyBaMM and DandeLiion now incorporate thermodynamics, mechanics and long-term ageing.

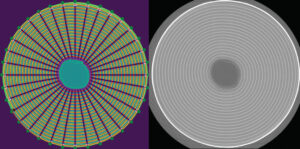

Cylindrical cell geometry discretisation example in 2D (approximately 2000 modelling cells). Each finite volume is simulated as an individual Newman model.

In two examples of Faraday Institution research moving to the next stage of commercialisation, the Power-Up and GENESIS projects, selected as two of the Faraday Battery Challenge Round 4 projects in what was a highly competitive bidding process, leverage the knowledge, capabilities and know-how of the team at Imperial College London and the wider Multi-scale Modelling team.

Commercialisation

About:Energy, a joint spin out from Imperial College London and the University of Birmingham has been set up to help commercialise the battery modelling capability developed by the Faraday Institution’s Multi-scale Modelling Project. The company aims to facilitate the use of battery modelling by UK industry, increasing the speed of battery prototype development and giving the organisations it works with a competitive advantage. Read the press release.

In December 2022, the Battery Parameter eXchange (BPX), an open standard for physics-based lithium-ion battery models, was launched. The standard defines the battery parameters, the equations that use the parameters, and the reporting of experimental measurements used to validate the reported parameters. The initiative aims to provide a common language to enable accurate battery modelling and reduce costs and time-to-market for industry.

Read the news release. Visit the BPX website:

Technical managers, whether working in automakers or SMEs, involved or interested in battery modelling, are encouraged to engage with the BPX standard to understand how it can benefit their business by contacting [email protected]

Project funding

£22.9m

1 March 2018 - 31 March 2025

Principal Investigator

Professor Gregory Offer,

Imperial College London

Project Leader

Dr Jacqueline Edge

Imperial College London

Project Manager

Silvia Gigli

Imperial College London

University Partners

Imperial College London (Lead)

University of Birmingham

University of Oxford

University of Bristol

University of Portsmouth

University of Southampton

University of Warwick

Research Organisations, Facilities and Institutes

UK Battery Industrialisation Centre (UKBIC)

+ 17 Industrial Partners

Comments are closed.